Powdered Metal Materials

Proform specializes in manufacturing powdered metal parts from a variety of materials that offer exceptional properties and customizable options to fit your application needs.

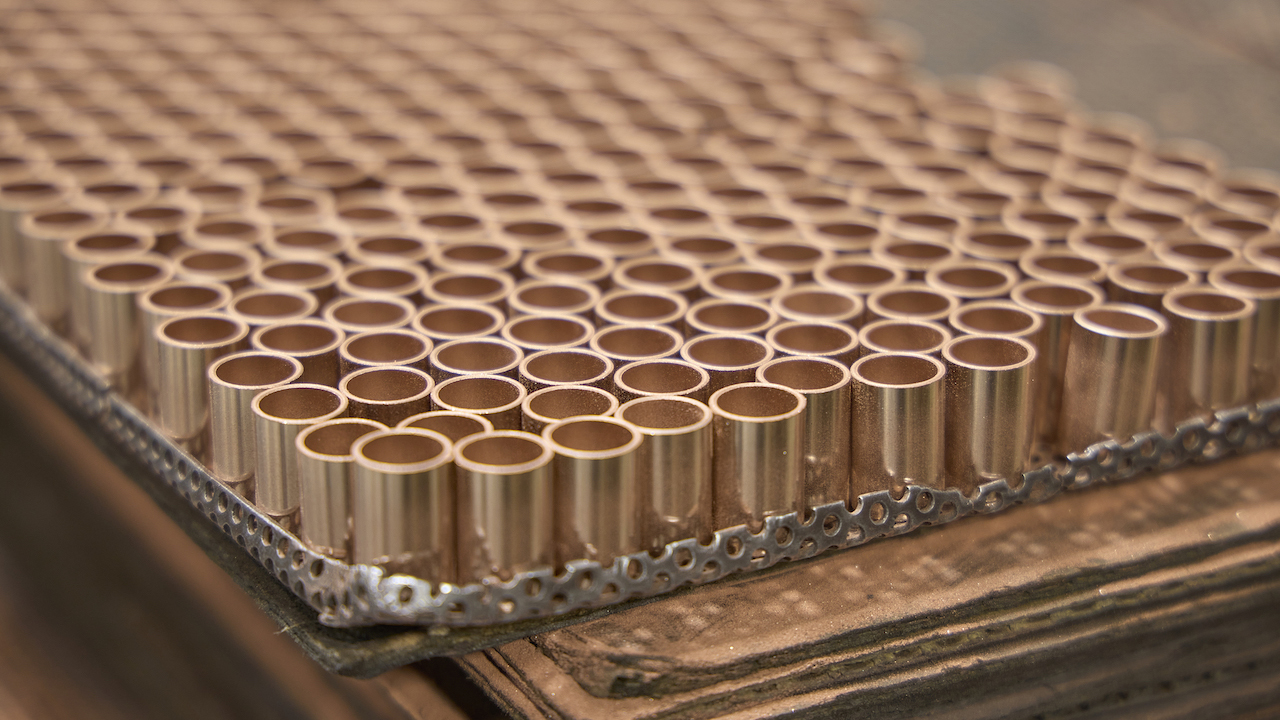

Bronze

Bronze offers excellent wear resistance, low friction, and self-lubricating properties, making them ideal for applications where reliable performance, extended service life, and reduce maintenance are desired.

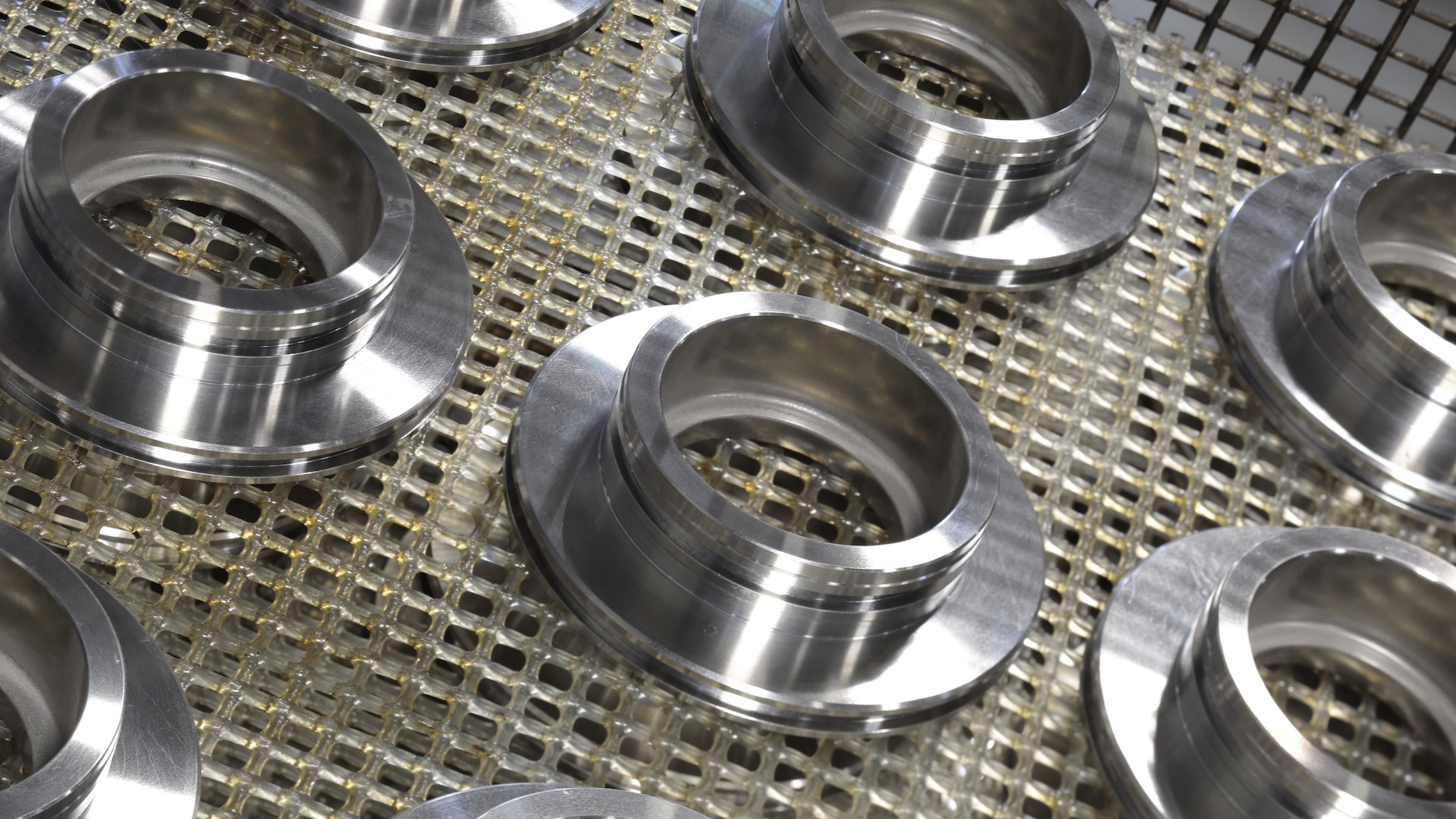

Iron

The use of iron as a material for bushings ensures robustness and resilience under heavy loads and challenging environmental conditions. Various alloys of iron material are available for use depending on application requirements.

Iron

The use of iron as a material for bushings ensures robustness and resilience under heavy loads and challenging environmental conditions. Various alloys of iron material are available for use depending on application requirements

Mixed Materials

Mixed materials utilize a mixture of bronze and iron to create a product focused selection of materials. Material mixes can range from 25% bronze to 75% with the balance being comprised of iron materials. By utilizing a mix of bronze and iron a cost effective material can be used to meet both performance and cost targets.

Aluminum

Aluminum’s light weight and strength result in an excellent strength-to-weight ratio. The design flexibility of aluminum allows our engineers to create the optimum shape and performance needed for your specific application. Our parent company, MPP is proud to be the global leader in the design and production of aluminum powder metal components.

Aluminum

Aluminum’s light weight and strength result in an excellent strength-to-weight ratio. The design flexibility of aluminum allows our engineers to create the optimum shape and performance needed for your specific application. Our parent company, MPP is proud to be the global leader in the design and production of aluminum powder metal components.

Soft Magnetic Composites

Soft magnetic composites (SMCs) are playing a crucial role in the shift to electrification. Each powder particle is coated with an insulation layer, thus allowing the PM process to press the parts to the net shape in a single pressing, creating the lamination stack for a brushless direct current motor (BLDC) application. Our parent company, MPP is proud to be an innovator in SMCs.

Ensuring our parts exceed your standards for more than 25 years

Leading producer of bronze powder metal worldwide